Aerospace

Growth in air traffic poses the question of how to achieve a more sustainable way of flying with a reduced amount of environmental damages and especially costs. One of the options to attain the lower cost flight is to utilize more electric power. Implementing the more electric technology in new aircraft "More Electric Aircraft (MEA)" achieves several advantage such as reducing the operation and maintenance cost and optimizing the performance:

Future aircraft will tend to use electrical power rather than hydraulic, pneumatic or mechanical power. At the core of this E-Drive are the gearbox, electric motor and power electronics inverter, with key functional issues being: high frequency operation, reliability, fault tolerance, power waveform quality, elevated temperature operation, and EMI regulation compliance.

These innovative E-drives will enable new system technologies for more environmentally friendly aircrafts.

What AE Group offersWithin future Aircrafts the associated electrical rotating machine weight increase can be a drawback for many MEA architectures. Consequently the AE Group aids aerospace customers to identify solutions to reduce the mass (torque/power density) of these machines by implementing:

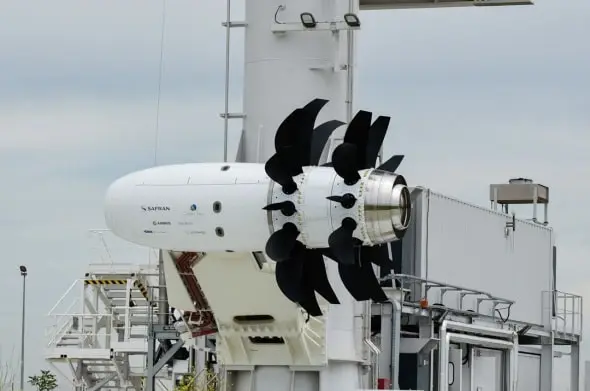

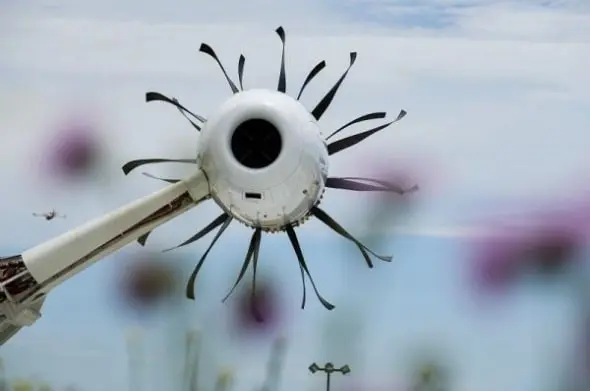

Under Europe’s Clean Sky research program, Safran ground-tested a full-scale counter-rotating open-rotor engine, showing substantial savings in fuel burn over the latest commercial turbofans and achieving significant reductions on noise over past open-rotor engines. The Open Rotor tests clearly show the importance of European research programs such as Clean Sky, which allow manufacturers to investigate "risky" technologies. Within Clean Sky, Advanced Electromagnetics B.V., Magnomatics Ltd, Romax Technologies, and the University of Sheffield, are assisting with several of the challenges that remain with the Open Rotor concept of Safran. Assisting them with challenges and technical feasibility is what we do best! Also looking for assistance? Please let the AE team know and we will be ready to contribute to your technical solution.

Please contact us at info@ae-grp.nl for more information.